Enercon Induction Cap Sealers

Amseal Closure Systems is your local cap sealing resource in New Zealand.

Enercon’s induction cap sealers are recognized around the world for preventing leaks and preserving freshness with hermetic seals for packagers of food, beverage, pharmaceuticals, health & beauty products, chemicals & petroleum packages.

Why choose Enercon? Enercon’s induction sealers are the world’s leading cap sealing technology. Super Seal™ induction sealing technology has sealed over 50 billion containers around the globe. From manual hand held cap sealing to high performance production line cap sealers. Enercon offers the most diverse range of induction sealer technology on the market.

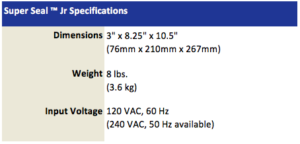

Super Seal Jr

The unit’s compact design and high level performance is a direct result of forward-thinking electronic architecture which features a proprietary device switching technique. The system is ideal for laboratory applications, manual production, off-line testing; and startup operations with aspirations of increased productivity.

An operator friendly display completes this powerful package. Users will benefit from a digital sealing timer, missing foil indicator, as well as an electronic batch and foil counter.

Read Full Info.

The unit’s compact design and high level performance is a direct result of forward-thinking electronic architecture which features a proprietary device switching technique. The system is ideal for laboratory applications, manual production, off-line testing; and startup operations with aspirations of increased productivity.

An operator friendly display completes this powerful package. Users will benefit from a digital sealing timer, missing foil indicator, as well as an electronic batch and foil counter.

Plug the system into a standard wall power outlet and it is ready to operate. Set the power level and the timer to the number of seconds the container requires for a strong and secure seal. To seal, simply place the sealing head on the container’s cap and press the trigger on the handle of the sealing head. The timer counts down to zero as power is applied into the cap to form the seal. Check the first few containers for seal quality. Adjust torque, power and time until a firm, but not scorched, seal is achieved. Once the correct settings are reached, seals will be secure and consistent.

When you need to transport or store the Super Seal™ Jr simply pack it into its convenient carrying case. This unit does not require water or special power so it can be used virtually anywhere. The Super Seal™ Jr. is extremely simple to handle, carry and operate and is the perfect answer to your portable induction sealing needs.

Super Seal™ Jr Standard Features

- Advanced circuitry and Enercon’s well-proven and ultra-reliable sealing head design

- Durable yet lightweight carrying case with a convenient compartment for the sealing head and power cords

- Digital timer to ensure accurate sealing

- Missing Foil indicator

- Batch counter

- Standard sealing head seals cap diameters up to 80mm, with available sealing head capable of sealing cap diameters up to 120mm

- Specialty sealing heads available

Super Seal™ Jr Available Options

Multiple sealing heads

The Super Seal™ Jr induction sealing system comes standard with one sealing head. The head packaged with your Compak Jr is chosen based on the containers you specify. If you are sealing a wide range of containers an additional head will provide you with capabilities to seal containers from the smallest closures to 120mm wide mouth containers.

Custom sealing heads

Do you have a unique closure? A container with a closure larger than 120mm? Enercon application engineers pride themselves on finding solutions to even the most unique applications. Contact us and we’ll work to find the solution that is right for you.

Upgrade to a conveyor custom sealing heads

When your production levels grow it may be time to upgrade. Choose between upgrading the Super Seal™ Jr to a conveyor based system or take advantage of our trade-in program and benefit from our high-powered Super Seal™ cap sealers.

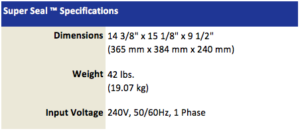

Super Seal

Enercon’s Super Seal™ cap sealer is the industry standard for air cooled cap sealing.

The Super Seal™’s reputation for reliable performance is well deserved. These remarkable cap sealers have sealed over 5 billion containers at production facilities around the globe.

Superior mechanical and electrical design make these sealers the most popular choice of packagers looking for reliable performance and ease of operation. The compact all-in-one power supply and sealing system requires little floor space and virtually no maintenance.

Read Full Info.

Enercon’s Super Seal™ cap sealer is the industry standard for air cooled cap sealing.

The Super Seal™’s reputation for reliable performance is well deserved. These remarkable cap sealers have sealed over 5 billion containers at production facilities around the globe.

Superior mechanical and electrical design make these sealers the most popular choice of packagers looking for reliable performance and ease of operation. The compact all-in-one power supply and sealing system requires little floor space and virtually no maintenance.

Enercon’s expertise also plays a significant role in the successful application of the Super Seal™ technology. Our engineering team has developed an assortment of custom sealing heads to meet almost every requirement imaginable. Matching the sealing head to an application optimizes productivity and efficiency.

Super Seal™ Standard Features

Second-to-None Reliability

The SuperSeal maximizes line efficiencies and uptime with advanced circuitry and the well proven Super Seal sealing head design.

Customized sealing heads with productive quick-change design

Enercon has engineered an assortment of sealing heads to meet the specific demands of a variety of package configurations and packaging operations. Our new quick change sealing head design makes changing sealing heads fast and easy.

Air-cooled. Water friendly.

The Super Seal™ is ideal for any packaging environment, even for wash-downs. That’s because the system’s electrical compartment is protected by a sealed cabinet.

Turnkey Solution

Add Enercon’s inspection system and eJector™ for a complete turnkey cap sealing solution.

Flashing Light Indicator

Alerts your operators to changes in operating status. Green when sealing head is energized, flashing red when sealing power is interrupted.

Mobile Cart

Provides optimal flexibility for moving sealer from line to line. Stainless steel cart features heavy duty castors and leveling pads.

Motion-Foil Detection Group

Protects your products in event of line back-up. Two sensors in one group: the first sensor is used to shut off power if containers back up under sealing head, the second sensor detects missing foil liner.

Super Seal Max

Increased cap sealing capacity is just the beginning. A new touch screen interface with one-click-away navigation intuitively unlocks a host of features that packagers will love. Complete cap inspection and container rejection operations are fully integrated, supervisory password security ensures proper operating settings and recipe management enables repeatable results for each container setup.

A full complement of bottle & foil counts, internal monitoring of all critical operating data, descriptive fault information, troubleshooting support, universal voltage input compatibility (200-240V), remote and local control modes and network connectivity make this the industry’s most powerful and comprehensive induction cap sealer. It is currently available in the United States, Canada and Europe. Meanwhile the first generation Super Seal™ Max continues to be available in the rest of the world.

Read Full Info.

Increased cap sealing capacity is just the beginning. A new touch screen interface with one-click-away navigation intuitively unlocks a host of features that packagers will love. Complete cap inspection and container rejection operations are fully integrated, supervisory password security ensures proper operating settings and recipe management enables repeatable results for each container setup.

A full complement of bottle & foil counts, internal monitoring of all critical operating data, descriptive fault information, troubleshooting support, universal voltage input compatibility (200-240V), remote and local control modes and network connectivity make this the industry’s most powerful and comprehensive induction cap sealer. It is currently available in the United States, Canada and Europe. Meanwhile the first generation Super Seal™ Max continues to be available in the rest of the world.

Twenty percent more induction sealing power with touch screen control

- Simple startup

- Quick Start Guide

- Universal input voltage compatibility (200V-240V

- Mechanically and electrically integrated cap inspection

- Stainless steel enclosure

Basic Operation

- Intuitive Touch Screen Control

- One-touch screen navigation

- Local Start/Stop

- Local Power Level Controls

- Compatible with Enercon’s current high-efficiency patented sealing heads

- Speaks 8 languages

Advanced Controls

- Supervisory password protection for operator lockout

- Recipe Control Mode

- All new cap inspection system

- Remote Start/Stop

- Remote Power Level Controls

- RS485 or Ethernet remote network control & monitoring

Internal Intelligence

- Monitoring of all critical operating data

- Container, cap, and foil counters

- Descriptive fault information

- Troubleshooting support

- Multiple language support

Super Seal Touch

Up to 20% More Sealing Power For Many Applications All New Cap Inspection System

- Sets up in minutes: pre-programmed and fully integrated with sealer

- Touch Screen control for inspection and rejection

- High sensitivity and responsiveness

- LED bottle centering guide

Internal Intelligence

- Easy-to-use and intuitive touch screen design

- Supervisory password protection with operator lockout

- Recipe management

- Internal monitoring of all critical operating data

- Container, cap, and foil counters

- Descriptive fault information

- Troubleshooting support

- Multiple language support

- Internal USB data port

Control Options

- Local and remote start/stop controls

- Local and remote power controls

- Remote network control and monitoring via RS485 or ethernet

And that’s not all!

- Stainless steel enclosure

- Microprocessor control

- Universal input voltage compatibility (200V through 240V)

- Advanced self protective circuitry for electrical components

- Compatible with Enercon’s current high-efficiency patented sealing heads